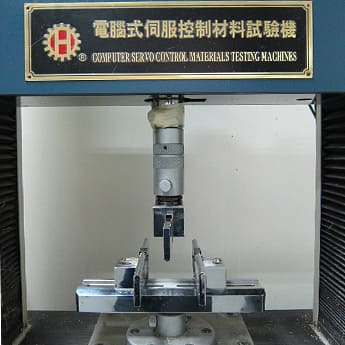

Atech owns and utilizes a professional laboratory and extensive testing equipment - such as a Material Testing Machine – which aid in examining the strength, rigidity and glass content of the FRP components produced. Atech provides high quality assurance from high-level inspection procedures in the pre-, mid- and post-stage of quality control. All of the raw materials are selected according to in-house laboratory. After raw materials are selected, incoming test will be conducted before applying into process. During the product manufacturing, Atech technicians implement inspections in each production stage. All the test results and manufacturing parameters will be collected to form a material database and all the information will before valuable reference for further process design and analysis.

In addition to Routine Tests, such as Mechanical Property, Resin Flow Test,Weather Resistance Test, Discoloration Test, Processbility Test, Fire Retardant Test, and Atech also focus on Advanced Test and Cross-Industrial Application. The Atech R&D team firmly believes that the highest quality products are derived only through the integration of thorough inspection technologies of the highest standards.

Mechanical Property, Resin Flow Test, Weather Resistance Test, Discoloration Test, Handleability Test, Fire Retardant Test

Innovation Technology and Process Research & Development

Integration of Cross-Industrial Technology towards Innovation

Tensile Strength/Modulus, Flexural Strength/Modulus, and Elongation Testing

ISO527-4、ISO14125、ASTM C393

Fiber Content Examination and Analysis

ISO 1887

Hardness Analysis

ASTM D2583

Property of Light Determination

ASTM E313

Surface Condition Analysis

ASTM E430

Coating Adhesion Determination

ASTM D4541

Viscosity and Thixotropy Measurement

ISO 2555

Temperature control for Accurate Viscosity and Thixotropy Measurement

ISO 2555